Fluoropolymer Coatings

Fluoropolymer Coatings, sometimes referred to as nano-coatings, effectively change the surface energy of the substrate they are applied to, so contamination from environmental contaminants, such as moisture, sulfur, pollution and grim is repelled from the surface.

The coatings are preferably applied via a dip coating system, resulting in the component surfaces being fully coated, unlike spray applications which tend to cover only the tops and side of the components. Once applied, the coating will dry to a thin transparent film, which has excellent hydrophobic and oleophobic properties. This differentiates fluoropolymer coatings from conformal coating i.e. acrylics or polyurethanes, which are not water repellent.

The coating is applied at <1-2um, dries in seconds, requires little or no masking and is removable and repairable. Cost reductions are achieved because of time savings in the processing of the printed circuit board.

We specialise in the application of both Certonal and 3M™ Novec™ Electronic Grade Coatings.

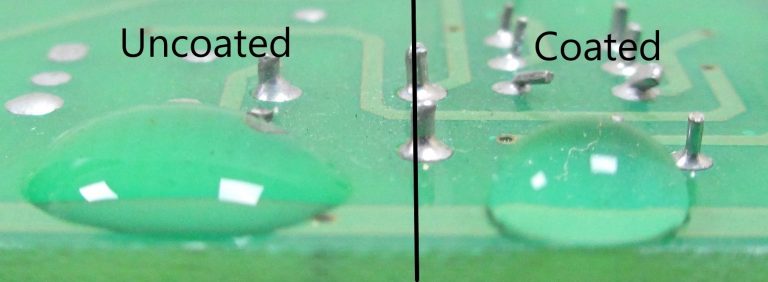

The below picture demonstrates how a droplet of water reacts to an uncoated and coated surface. The contact angle of the water droplet on the coated surface is greatly reduced, allowing the water droplets to bead up and drain freely from the surface.

Nano coating Benefits

Five reasons to use nano coatings as an alternative to traditional conformal coating:

- Cost advantageous.

- Excellent repellency,anti-wetting and anti-sticking properties against liquids, water, hydrocarbons, silicones, and photoresists

- Hydrophobic and oleophobic properties.

- Possibly no masking requirements.

- Full coverage of the PCB, even under and behind components structures.

- Reworkable.

- Low environmental impact compared to alternative coating solutions.

Arrling

Services

Arrling

Services